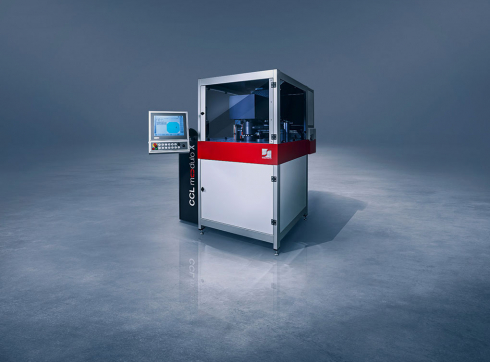

Fully-automated in-line quality inspection

With PMD Modulo SCHNEIDER introduces quality inspection to the fully automated production environment. For the first time blocked lenses can be measured automatically in-line without interrupting production.

New super dynamic

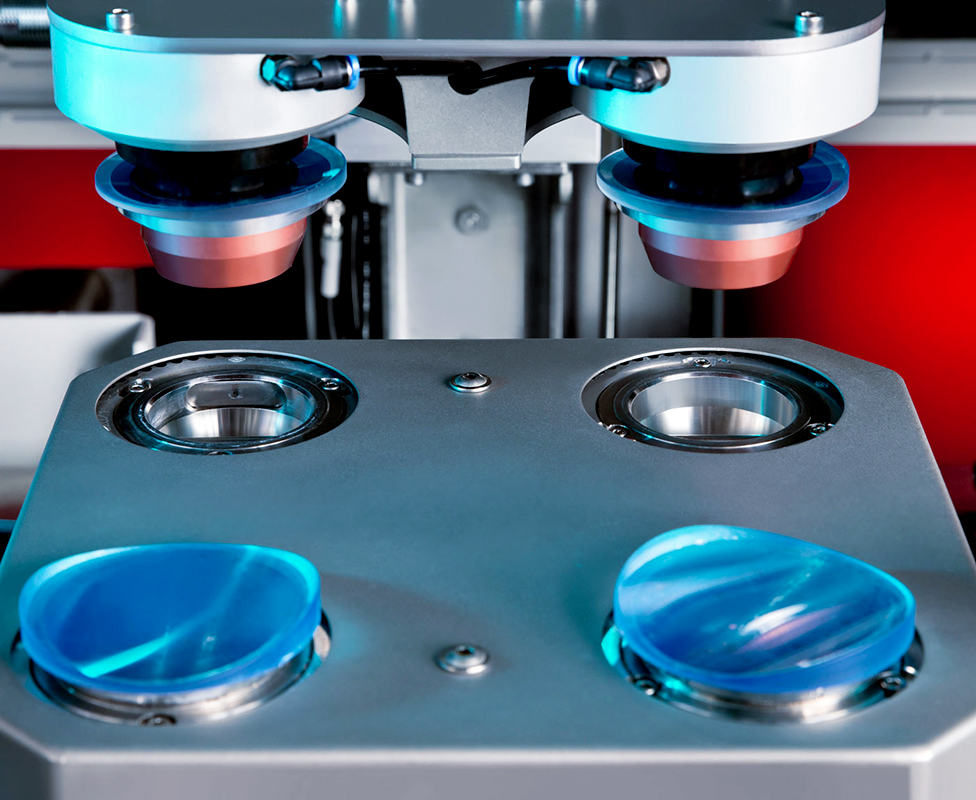

motor concept

Utilizing UV light for deflectometrical measurement, PMD Modulo is unaffected by common issues with transmissive measurements. It measures diopters and cosmetics directly and non-destructively based on one sole reflection. No need to deblock the lens.

PMD Modulo evaluates lenses on the fly with high resolution and without touching the lens. For the first time, on-the-block lens measurement occurs right after lens surfacing, avoiding the drastic time gap between manufacturing and quality inspection of current productions.

Opening up extensive analysis options

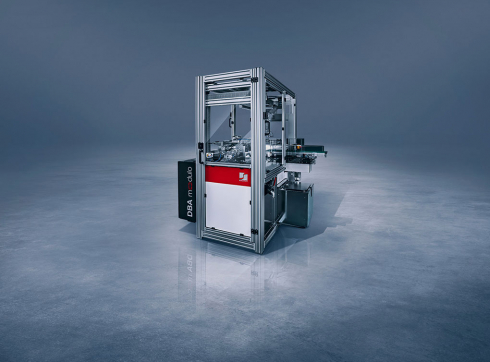

Maximum value is gained from the UV-PMD in conjunction with the Modulo Control Center. Integrating the PMD into the Modulo system opens up extensive new opportunities to analyze the collected data. The results are various new options and features that can considerably increase the value of your production line, e.g. a quality gate and quality trend recognition.

Benefits PMD modulo

Automated in-line measurement

Measurement of blocked lenses in production

On the fly lens evaluation

Rx and freeform measurements

Diopter and cosmetics measurement

Supports the new cognitive Modulo machine philosophy

Download

PMD modulo brochure

Technical Data

lens material

all organic materials

surface

polished

measurement area

up to 80 x 80 mm

measurement range

concave:

base curve r=-62,5 mm ... ∞

cylinder curve r=-50 mm ... ∞

convex:

base curve r= 80 mm ... ∞

cylinder curve r= 80 mm ... ∞

measurement accuracy

+/- 0.03 dpt

power consumption

4.9 kVA avg.

air requirement

min. 6 bar (87 psi)

machine weight

approx. 1150 kg (2536 lb.)

dimensions without control panel (width x depth x height)

approx. 1740 x 1320 x 1715 mm (69 x 52 x 68 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.