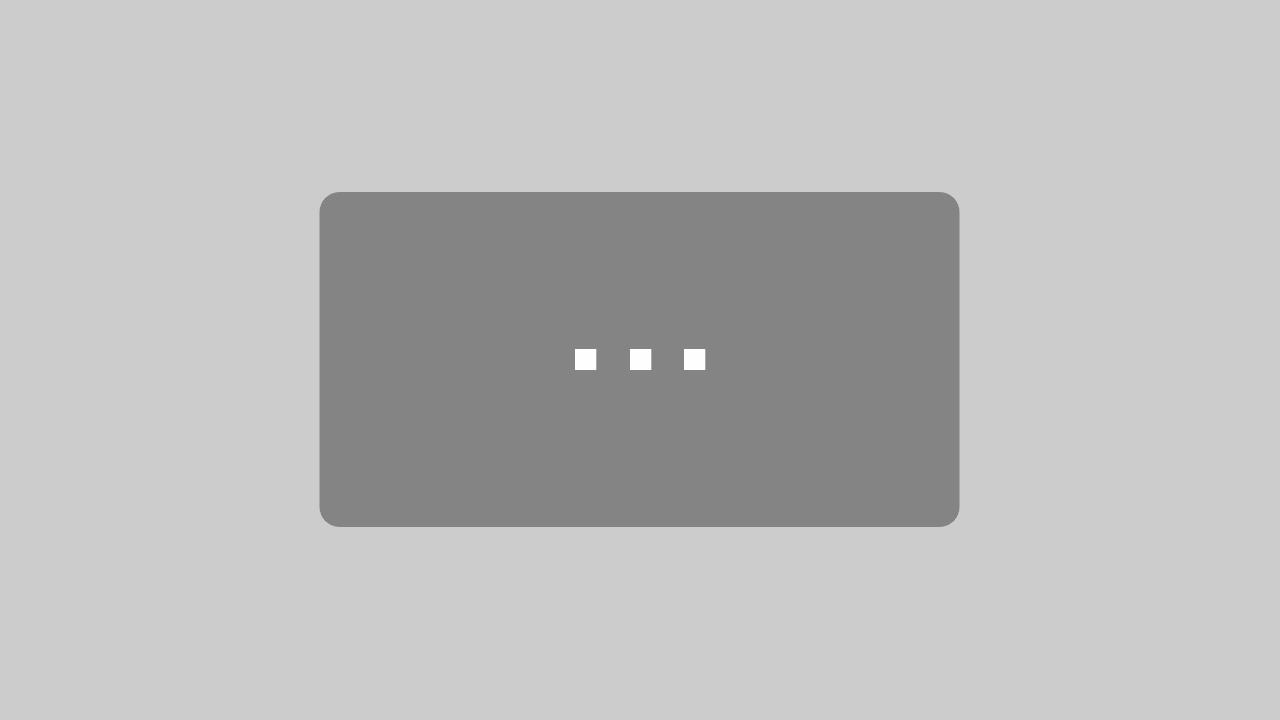

Powerful and efficient inline cleaning

The LCU Modulo is a fully automated and integrated lens cleaning system with brushes. The machine represents a powerful and efficient inline system to remove contaminations like adhesive residues or fingerprints and to prepare all different kinds of lenses for subsequent coating processes.

Full automation

After drying an optional unloading robot PRA, which can be easily integrated into the LCU Modulo, takes the lenses out of the running belt and puts them back in the coating job tray. If needed, the lenses are transferred on a conveyor belt leading directly to a cosmetic inspection area as well as the preparation area for the hard coating.

The Modulo advantage

LCU Modulo comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Modulo Control Center. The lab manager is fully informed about the current status of the machine. Therefore critical situations and downtime

can be avoided before they arise. Higher uptimes and increased yields are guaranteed.

Watch LCU modulo in action!

Benefits

Fully automated inline process

In-line brush cleaning of up to 300 lenses/hour

Additional impulse drying option for drying process

Automated loading and unloading option

No pre-cleaning needed

Low cleaning costs per lens

Short ROI periods

Download

LCU modulo brochure

Technical Data

lens diameter

40 – 80 mm

lens material

all organic and mineral materials

option

flow heater for DI-Water and PRA for automatic unloading

power consumption

35 kVA

air requirement

min. 6 bar (87 psi)

water requirement

DI-water conductivity < 1 μScm, 1,5 l/min

machine weight

approx. 1800 kg (3968 lb.)

dimensions (width x depth x height)

approx. 2000 x 1615 x 1930 (79 x 64 x 76 inches)

with automation: approx. 8530 x 3384 x 2860 mm (336 x 133 x 113 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.