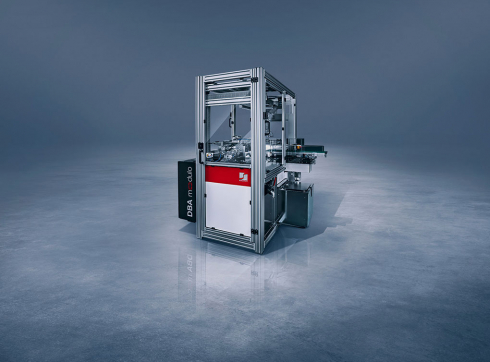

Two processing steps,

one machine

Designed as a perfect supplement to the CCB Modulo, the DTS Modulo provides a smooth and efficient technology for deblocking and tape-stripping of two lenses simultaneously.

Suitable for all lens materials, the DTS Modulo is the optimal choice to meet the demands of mid- and highperformance labs.

Maximum ease of use

The block pieces are sorted in boxes and prepared for quick reuse in the CCB Modulo, guaranteeing maximum ease of use.

Swift and easy disposal

The tape and EFT material are collected using a band filter system and can be disposed of easily.

The Modulo advantage

DTS Modulo comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Modulo Control Center. The lab manager is fully informed about the current status of the machine. Therefore critical situations and downtime

can be avoided before they arise. Higher uptimes and increased yields are guaranteed.

Benefits

Fully automated deblocking and tape-stripping in one unit

Automated cleaning and sorting of block pieces

Highest throughput

Lowest danger of lens breakage

Easy plug & play installation

Low maintenance

Supports the new cognitive Modulo machine philosophy

Download

DTS modulo brochure

Technical Data

lens diameter

up to Ø 85 mm

lens material

all organic materials

power consumption

10 kVA avg.

air requirement

min. 6 bar (87psi)

machine weight

approx. 850 kg (1874 lb.)

dimensions (width x depth x height)

approx. 1750 x 1800 x 1715 mm (69 x 71 x 68 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.