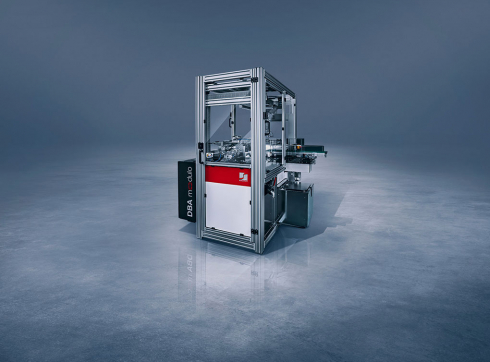

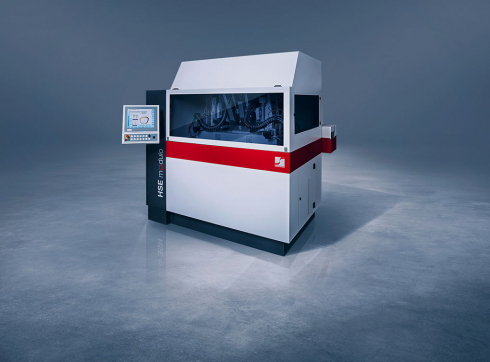

Fully automated

for highest throughput

The powerful excimer laser, CCL Modulo X, has been designed for the fully automated production environment providing highest throughput and excellent marking quality.

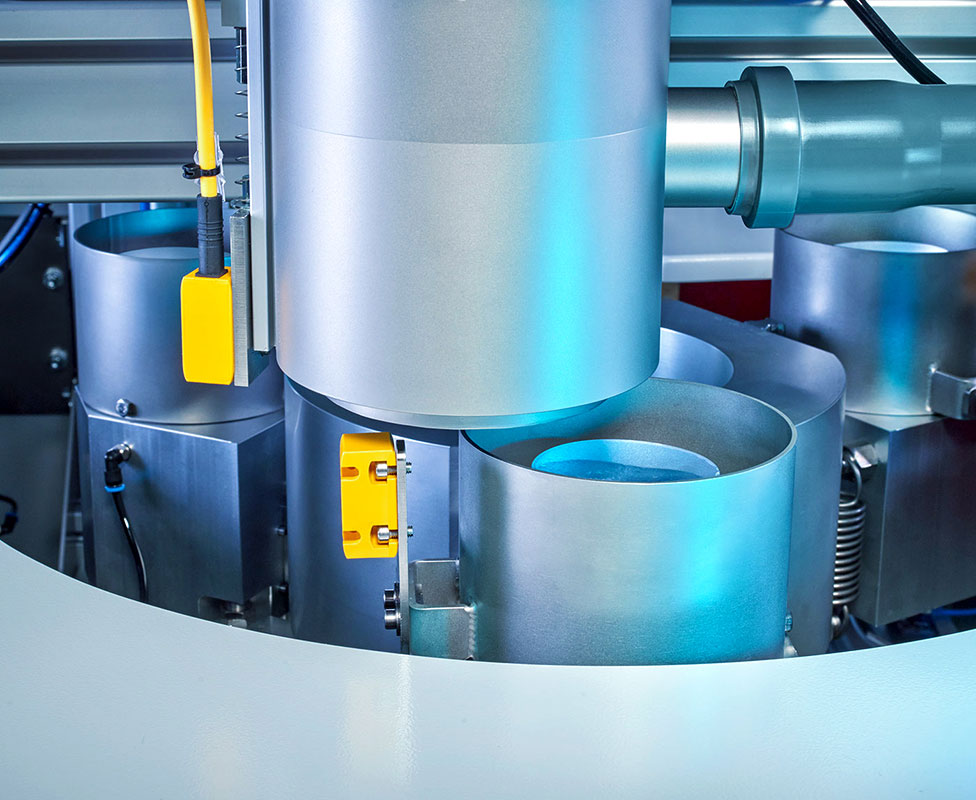

Its three stations and fast automation support simultaneous loading, marking, and unloading, to reduce non-productive times to an absolute minimum.

Unlike other excimers, CCL Modulo X relies on a new ultra-fast full lens scanning concept that allows marks anywhere on the lens without time consuming lateral lens repositioning. The result is a significantly higher throughput compared to other excimers.

New full lens scanning concept

CCL Modulo X marks anywhere on the lens without time consuming lateral lens repositioning.

Superior excimer laser marking quality

The laser intensity can be easily adjusted according to the requirements.

Whether logos, symbols, additions or other markings, the powerful Argon Fluoride laser consistently produces high-quality markings on all organic and mineral materials. Ablating the material, heat affected zones are prevented that may cause problems such as color deviations and chromatic aberrations in the subsequent coating or tinting process.

The combination of high throughput, highest-quality results, low running costs, and low maintenance makes CCL Modulo X a sound investment for any larger lab.

Watch CCL Modulo X in action!

Benefits

Consistently high throughput of 300+ lenses/hour

Excellent marking quality on any material

Adjustable laser marking visibility

Long-lasting laser

Low maintenance

Efficient energy monitoring

High safety standards

Supports the new cognitive Modulo machine philosophy

Download

CCL modulo X brochure

Technical Data

lens diameter

All organic and mineral glasses

marking field size

ø 100 mm

dot size

approx. 80 μm

accuracy

+/− 30 μm

clamping system

block ø 43 mm

power consumption

1 kVA avg.

air requirement

6 bar (87 psi)

laser safety

laser class I

machine weight

approx. 600 kg (1323 lb.)

dimensions without control panel (width x depth x height)

approx. 1275 x 1450 x 1800 mm (51 x 57 x 71 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.