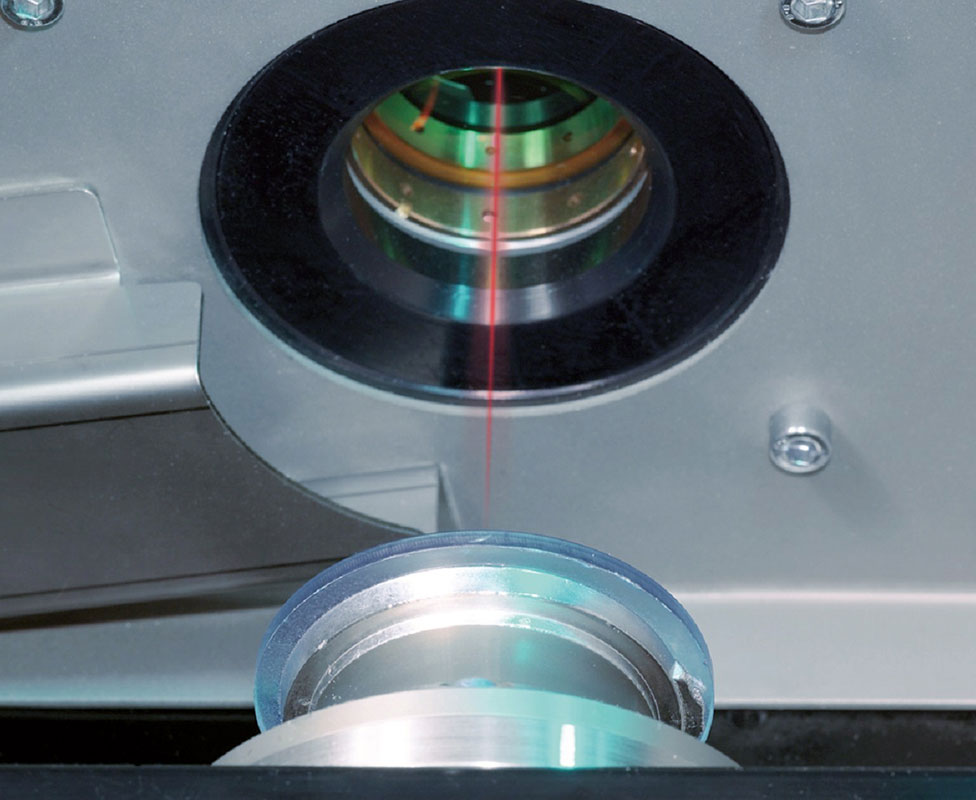

Industry proven CO2 laser

With the CCL Modulo laser marking system, fine markings are accomplished with ease and precision.

Based on an industry-proven CO2 laser, we refined the laser performance by implementing a proprietary actively controlled laser stabilization circuit.

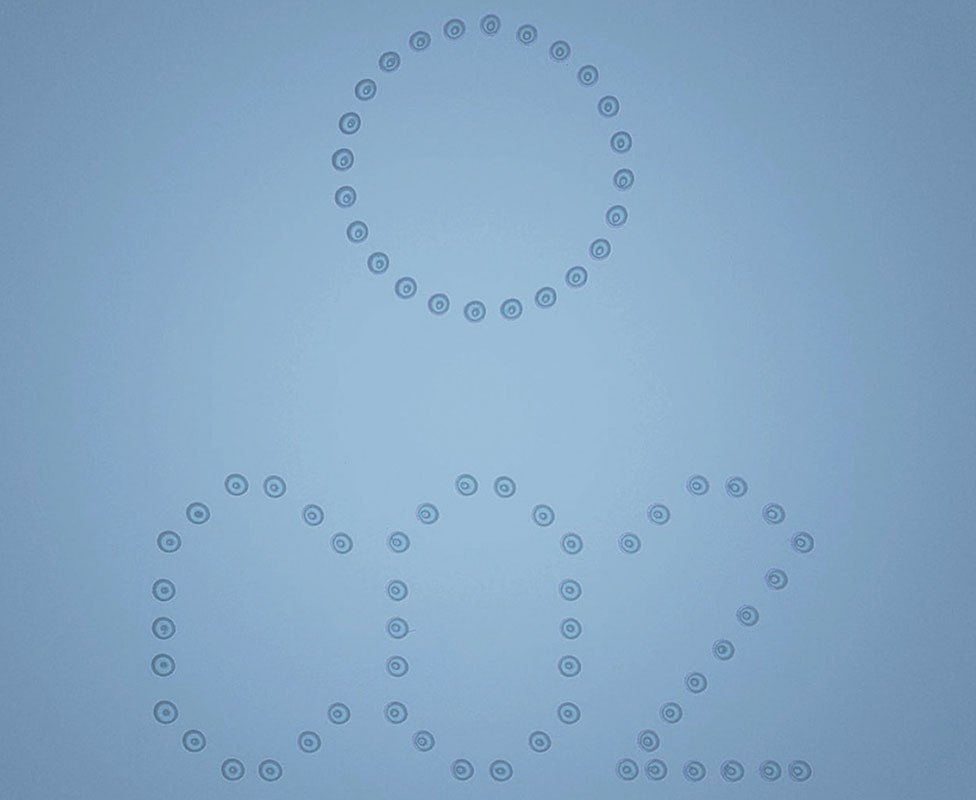

Fine and consistent patterns

The result: you get consistent high-quality laser markings day after day and year after year without operator intervention.

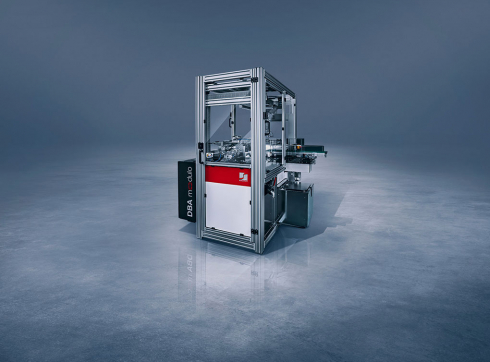

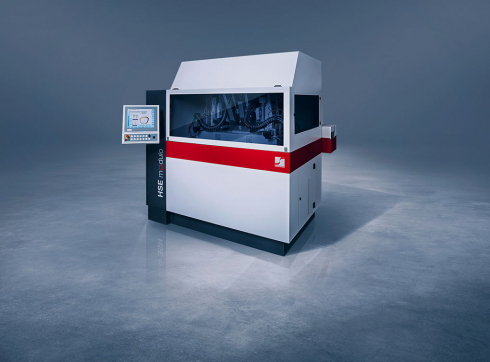

The CCL Modulo has been designed for a wide range of marking requirements handling essentially all jobs in line. The robust design and implemented safety features exceed international safety regulations, reducing operator intervention to a minimum.

Benefits

High-resolution marking

Actively controlled laser stability

Highest consistency of markings

High throughput

Adjustable laser marking visibility

No consumables

Automated operation

Minimum maintenance

High safety standards

Supports the new cognitive Modulo machine philosophy

Download

CCL modulo brochure

Technical Data

lens material

CR39, Hi-index, Polycarbonate, Trivex®

marking field size

Ø 65 mm

dot size

approx. 100 μm

accuracy

+/- 30 μm

clamping system

block Ø 43 mm

power consumption

2 kVA avg.

air requirement

min. 6 bar (87 psi)

laser safety

laser class Ι

machine weight

approx. 420 kg (926 lb.)

dimensions without control panel (width x depth x height)

approx. 900 x 1320 x 1715 mm (36 x 52 x 68 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.